The method of controlling the water pump can be divided into the following simple steps:

1. Turn on the power: Make sure the water pump is connected to the power supply and the power is on.

2. Start the water pump: Press the start button or turn on the switch, and the water pump will start working.

3. Adjust the flow: By adjusting the control valve on the water pump, the water flow can be controlled.

4. Stop the water pump: When you need to stop, press the stop button or turn off the switch, and the water pump will stop working.

5. Disconnect the power: After use, remember to cut off the power supply to ensure safety.

In this way, you can control the water pump simply and effectively.

However, we will not always have time to actively adjust the control valve of the water pump, so we will use the water pump controller (water pump control box) to adjust it intelligently. This ensures that the water pump is running at the most appropriate flow at any time.

The water pump controller is an intelligent device that can automatically monitor the operating status of the water pump and adjust the working parameters of the water pump according to actual needs. There are several benefits of using a water pump controller:

1. Automatic adjustment: The water pump controller can automatically adjust the operation of the water pump according to parameters such as water level and pressure to ensure that the water pump always works in the best condition.

2. Energy saving and power saving: Intelligent adjustment can avoid excessive work of the water pump and reduce energy waste, thus achieving energy saving effect.

3. Extend life: Stable operation can reduce the wear of the water pump and extend its service life.

4. Convenient management: No frequent manual intervention is required, which reduces the complexity of operation and improves the efficiency of management.

By using the water pump controller, we can realize the intelligent management of the water pump, ensuring that the water pump can work at the most suitable flow rate at different times and situations, providing reliable protection for our daily life and production.

Do I need a water pump control box for well pump?

Whether you need a water pump control box for your well pump depends on the type of well pump you have and its specific requirements. Here are some considerations:

Type of Well Pump:

Submersible Well Pumps: Most submersible well pumps, especially those that are three-wire models, require a control box. The control box houses the starting components, such as the capacitor and relay, that are necessary for the pump to start and operate efficiently.

Jet Pumps: These pumps, typically used for shallow wells, generally do not require a separate control box as the motor is above ground and the starting components are built into the pump itself.

Pump Specifications:

Two-Wire vs. Three-Wire Submersible Pumps: Two-wire submersible pumps do not require a separate control box because all the necessary starting components are built into the motor. However, three-wire submersible pumps do need a control box to house these components externally.

Pump Motor Requirements:

If your well pump motor specifies the need for a control box, it is essential to use one to ensure the proper functioning and longevity of the pump. The control box helps manage the electrical flow and protects the motor from potential damage due to irregular power supply.

In summary, if you have a three-wire submersible well pump, you will need a control box. For two-wire submersible pumps and most jet pumps, a control box is typically not required. Always check the manufacturer's specifications and guidelines to determine the exact requirements for your well pump system.

How does a water pump controller work?

A water pump controller works by automating the operation of a water pump, ensuring it runs efficiently and effectively based on specific conditions and parameters. Here's a simple explanation of how it functions:

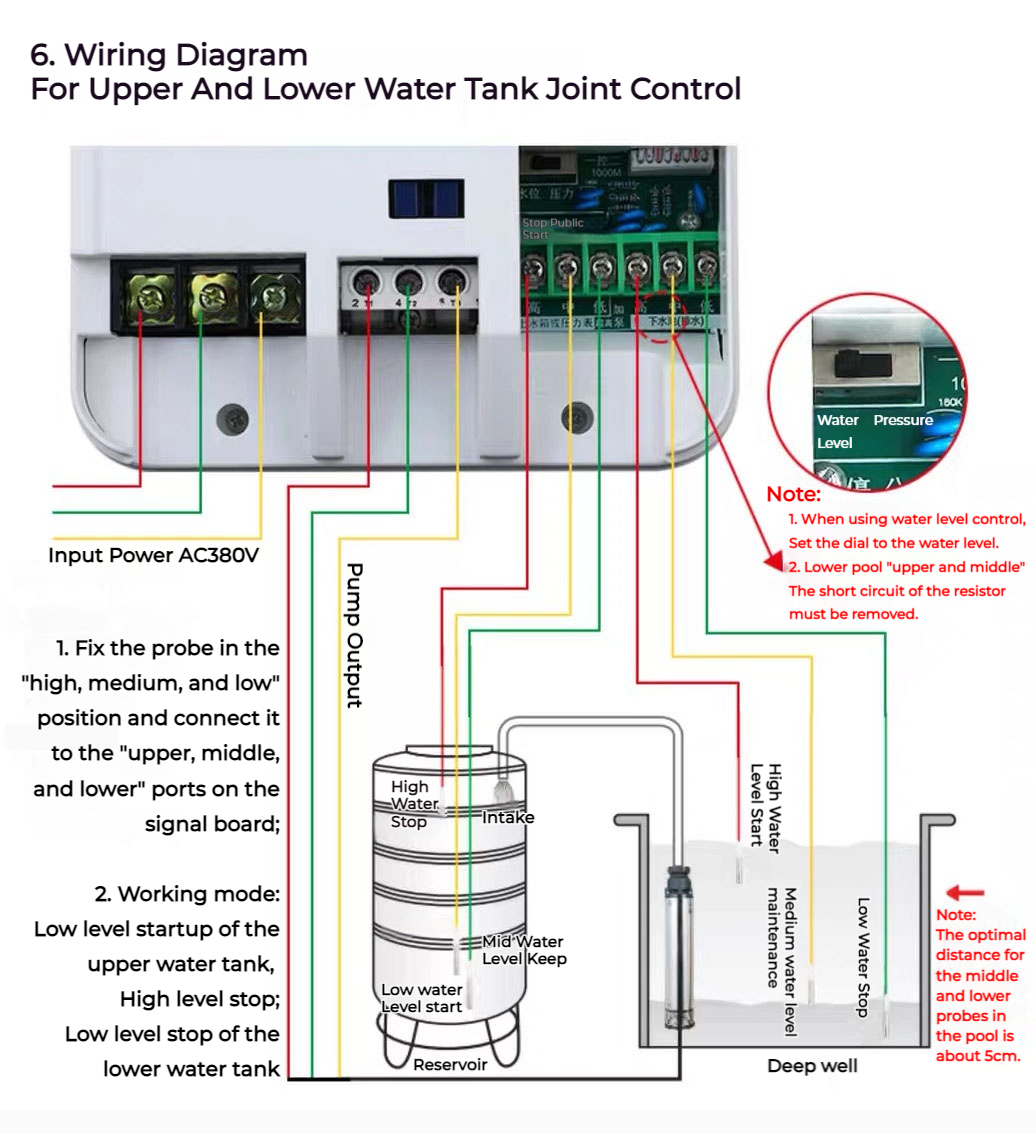

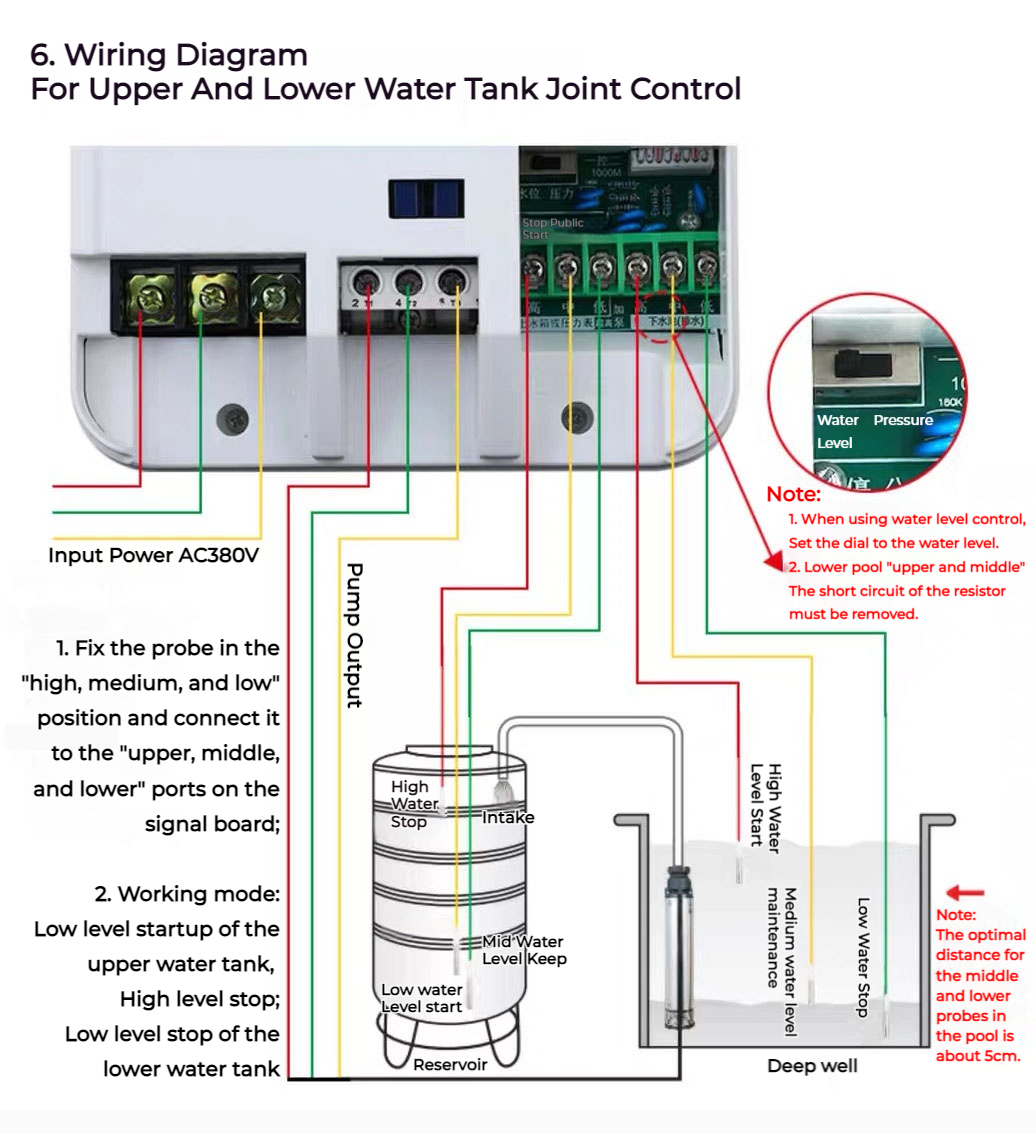

Monitoring Inputs: The controller constantly monitors various inputs such as water levels, pressure, flow rates, and other relevant data. This is usually done through sensors placed in the water system.

Decision Making: Based on the inputs it receives, the controller makes decisions about when to start or stop the pump. For example, if a water tank reaches a certain low level, the controller will turn the pump on to fill the tank. Conversely, if the tank reaches a high level, the controller will shut the pump off to prevent overflow.

Starting the Pump: When the controller decides the pump needs to run, it sends a signal to the pump's motor to start it. This process often includes soft-start features to gradually increase the pump's speed, reducing the mechanical stress and electrical surge.

Adjusting Operation: Some advanced controllers can adjust the pump's operation dynamically. They can control the speed of the pump motor (in variable speed pumps) to match the required flow rate, thereby improving efficiency and reducing energy consumption.

Stopping the Pump: When the desired condition is met (e.g., the water tank is full, or the pressure reaches the set point), the controller sends a signal to stop the pump. This ensures that the pump doesn't run unnecessarily, which can save energy and reduce wear and tear.

Protection Features: Water pump controllers often include various protection features to safeguard the pump and the system. These can include:

Dry Run Protection: Prevents the pump from running without water, which can cause damage.

Overload Protection: Shuts down the pump if it draws too much current, protecting the motor from overheating.

Surge Protection: Protects against voltage spikes that can damage electrical components.

Feedback and Alerts: Many controllers provide feedback through displays or alerts, informing the user about the pump's status, any errors, or maintenance needs. Some advanced models can be integrated into smart home systems, allowing remote monitoring and control via smartphones or computers.

In summary, a water pump controller automates the management of a water pump, ensuring it operates based on real-time conditions, thus optimizing performance, conserving energy, and protecting the system from damage.